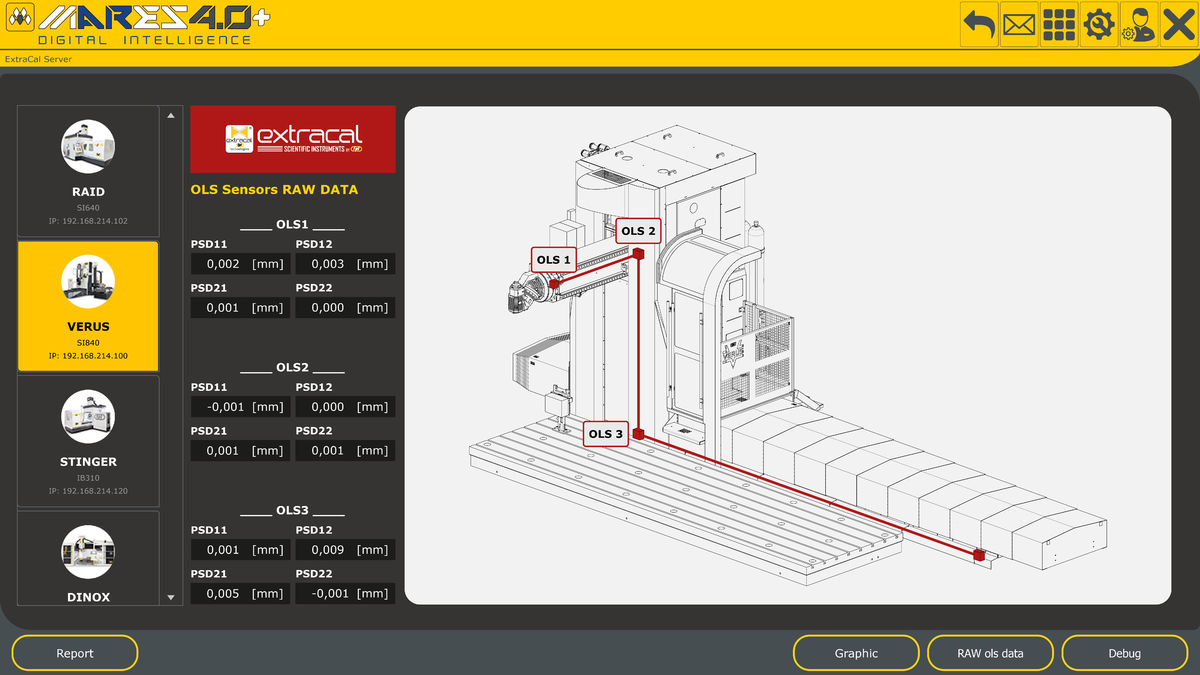

Extracal is an innovative measuring system, that operates in real time and measures the position of the working axes independently from the structural strains and/or bending stress of the machine.

For the first time a milling or boring machine is able to certify the machined workpiece measurement with the same accuracy of a 3D measuring machine, saving lots of time and huge costs of machined workpiece movement, particularly if they are of big-sized dimensions.

It allows to introduce suitable corrections to the machine tool so that to automatically restore the machine axis calibration, without any additional device and granting the accuracy.