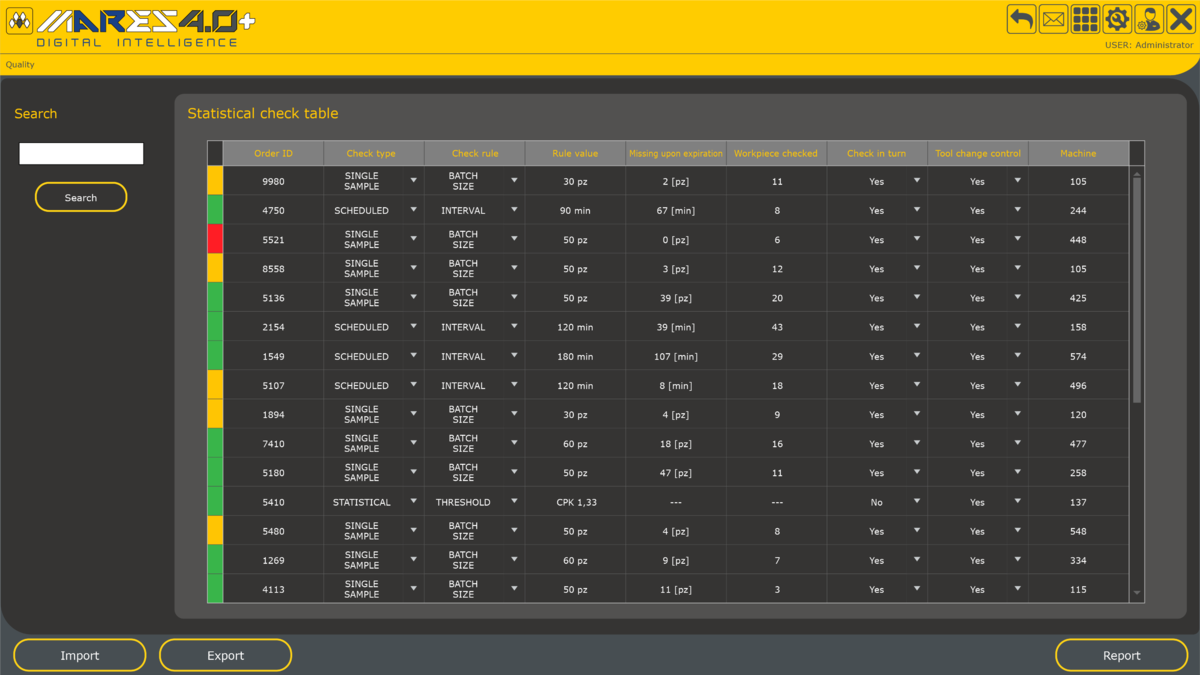

QUALITY application plans the quality controls foreseen, manages the control plans of production batches and monitors the quality trend of the production process.

The documents relevant to workpiece control methods can be associated with the production batch through JOB MANAGER application. They can be consulted in the machine through JOB CLIENT application.

The outcome of workpiece control is recorded in a table, which records also the values detected during the measurement, afterwards the execution of the control is confirmed. The data entered are automatically associated with the production order.

Quality trend foresees scrap management. It is the machine operator who manually enters into JOB CLIENT application the data relevant to production scraps.

It is available a synoptic, which contains all the machines in production with their operating state, the number of workpieces produced and to be produced, the number of workpieces controlled and information whether workpiece control was performed or is in progress.